Rapidly becoming a revolutionary force, digital twin technology is transforming industries by offering a level of knowledge and optimization never before possible. Digital twins have a huge impact on everything from supply chains to customer experiences. The advantages, uses, and real-world examples that highlight the technology’s potential will all be covered in this article. Digital-Twin

Rapidly becoming a revolutionary force, digital twin technology is transforming industries by offering a level of knowledge and optimization never before possible. Digital twins have a huge impact on everything from supply chains to customer experiences. The advantages, uses, and real-world examples that highlight the technology’s potential will all be covered in this article.

Digital-Twin Technology: What is it?

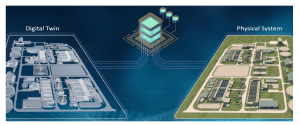

Fundamentally, digital-twin technology is the process of creating a virtual version of a real system, process, or object. Because it is linked to real-time data, this digital counterpart can replicate conditions and behaviors that are similar to those found in the actual world. Digital twins can be updated continually to reflect changes through the integration of sensors and Internet of Things devices, providing a dynamic and real-time model that improves decision-making.

Digital-Twin Technology Advantages

Image by Yandex.com

Improved Ability to Make Decisions:

Digital twins give companies predicted insights and real-time data. This implies that businesses may model different scenarios and run simulations to help them make well-informed decisions. Manufacturers, for instance, can prevent downtime and save money by anticipating possible equipment breakdowns.

Efficiency in Operations:

Businesses may improve workflows, save waste, and boost throughput by digitally testing and modeling processes. This talent has proven particularly useful in intricate sectors like manufacturing and aerospace.

Shorter Time to Market:

Because digital twins allow businesses to virtually create, test, and iterate concepts, they greatly aid in product development. This speeds up the release of new items and lowers the time and expense involved with physical prototypes.

Enhanced Resilience and Agility:

Organizations can react to market changes and disruptions more quickly with the aid of digital twins. Digital twins of the supply chain, for example, can adjust to real-time data, helping companies anticipate and minimize possible delays or interruptions.

Improved Customer Experience:

By creating customer digital twins, companies can analyze user behavior and preferences. This allows for personalized experiences and more effective marketing strategies.

Sustainability and Environmental Impact:

Digital twins contribute to sustainability by optimizing resource use and reducing waste. For example, they help in minimizing scrap during the production process, thereby supporting eco-friendly practices.

Real-World Examples of Digital-Twin Technology

1. Emirates Team New Zealand

Image by Yandex.com

One of the most compelling examples of digital-twin technology is Emirates Team New Zealand. By developing a digital twin of their sailing environment, the team was able to test thousands of hydrofoil designs virtually. This technology allowed them to optimize their boat designs without physically building each one, saving significant time and resources and contributing to their success in competitive sailing.

2. SpaceX

SpaceX has integrated digital-twin technology to create a virtual model of their Dragon capsule. This digital replica is used to monitor and adjust propulsion systems, trajectories, and loads. The result is improved safety and reliability during space missions, showcasing how digital twins can enhance complex engineering projects.

3. SoFi Stadium

SoFi Stadium utilizes a digital twin to aggregate data from various sources, including structural information and real-time football data. This comprehensive approach helps optimize stadium management and operations, ensuring a seamless experience for event attendees.

Case Studies Highlighting Digital-Twin Success

Anheuser-Busch InBev

Anheuser-Busch InBev (AB InBev), a global brewing company, has leveraged digital-twin technology to revolutionize its brewing and supply chain processes. The company developed a digital twin that models the brewing process and adjusts inputs based on real-time conditions. This allows AB InBev to automatically compensate for production issues, such as full vats or equipment bottlenecks, ensuring continuous and efficient production. The outcome has been a significant reduction in downtime and increased production efficiency.

Mercedes-Benz

Mercedes-Benz has taken customer experience to new heights by creating digital twins of their vehicles. Potential customers can interact with these digital models to “test drive” vehicles virtually. This immersive experience has helped the company boost sales and customer engagement, demonstrating the power of digital twins in enhancing top-line growth.

Types of Digital-Twin Technology

Digital twins come in various forms, each serving different purposes:

- Product Twins: These represent physical products and cover their entire lifecycle, from initial design to in-service operation. Product twins are essential for understanding product performance and identifying areas for improvement.

- Data Twins: A prime example is Google Maps, which functions as a digital twin of the Earth’s surface. Data twins use real-time information to optimize routes and help users navigate more efficiently.

- System Twins: These twins model interactions between different processes and components, such as manufacturing lines or supply chains. By simulating these interactions, businesses can identify inefficiencies and improve system performance.

- Infrastructure Twins: Infrastructure twins are used to represent large physical structures like buildings, stadiums, or bridges. These twins aid in maintenance, monitoring structural integrity, and ensuring safety.

How Digital Twins Enhance Supply Chain Management

Image by Yandex.com

Supply chain disruptions are a costly challenge for businesses. On average, such disruptions can impact up to 45% of a company’s cash profit in a year. To mitigate this risk, 86% of companies are investing in supply chain transformation—with digital twins ranking among the top three priorities.

A supply chain digital twin consolidates data from every aspect of operations to create a comprehensive model of the supply chain. This model enables leaders to:

- Run simulations: Test various supply-and-demand scenarios and see the potential impact on the supply chain.

- Optimize inventory: Track in-transit inventory and predict stock shortages or excesses.

- Enhance transparency: Meet regulatory requirements by providing upstream visibility into sourcing and manufacturing practices.

Companies that use supply chain digital twins have reported faster decision-making capabilities—up to 90% faster—and have experienced up to 20% improvements in customer delivery reliability.

Challenges in Implementing Digital-Twin Technology

Despite its benefits, implementing digital-twin technology comes with its challenges. Key obstacles include:

- Data Quality and Infrastructure: Digital twins rely heavily on high-quality data. Organizations need a robust data infrastructure capable of supporting continuous data flow from both live and testing environments.

- Change Management: Adopting digital twins requires a shift in company culture and operations. This change can be challenging without strong leadership and a clear strategy.

- Technical Expertise: Developing and maintaining digital twins require skilled professionals adept in IoT, AI, and data analytics. This may necessitate significant investments in talent acquisition and training.

Digital Twins and Generative AI’s Future

Digital twins are becoming more capable thanks to generative artificial intelligence (gen AI). By automating the production of code, organizing data inputs, and synthesizing outputs, Gen AI can expedite the development of digital twins. Large language models (LLMs), for instance, can help developers create digital-twin prototypes more quickly. Digital twins also give gen AI a test-and-learn environment, which increases its potential.

Sustainability Benefits of Digital Twins

Initiatives for sustainability greatly benefit from the use of digital twins. Digital twins assist businesses in minimizing their environmental effect through material waste reduction and product design optimization. For example, the usage of digital twins has helped manufacturers cut scrap waste by about 20%. Additionally, supply chain digital twins ensure sustainability throughout the process by striking a balance between cost and speed while incorporating environmentally friendly methods.

Final Thought

Digital twin technology is more than just a catchphrase; it is a potent instrument that propels sustainability, efficiency, and innovation in a variety of sectors. Digital twins provide a competitive edge in everything from improving product development to strengthening supply chains. Digital twins are poised to transform how companies function and thrive in a world that is changing quickly thanks to ongoing developments and integration with technologies like generative AI. Businesses who use digital twins effectively now will be in a strong position to dominate their sectors in the future.