High-Security Barrel Nuts for Playground Installations: When designing and building playgrounds, ensuring safety is the top concern. Every component, from slides to climbing frames, must meet rigorous standards to ensure the protection of children at play. Among the essential fastening solutions for modern playgrounds are high-security barrel nuts, known for their tamper-resistant features and superior

High-Security Barrel Nuts for Playground Installations: When designing and building playgrounds, ensuring safety is the top concern. Every component, from slides to climbing frames, must meet rigorous standards to ensure the protection of children at play. Among the essential fastening solutions for modern playgrounds are high-security barrel nuts, known for their tamper-resistant features and superior holding strength. These specialized fasteners not only enhance the structural integrity of play equipment but also contribute to long-term safety and maintenance efficiency.

This article explores the critical role of high-security barrel nuts/ mur in playground installations, outlining their advantages, applications, and best practices for selection and use.

What Are Barrel Nuts?

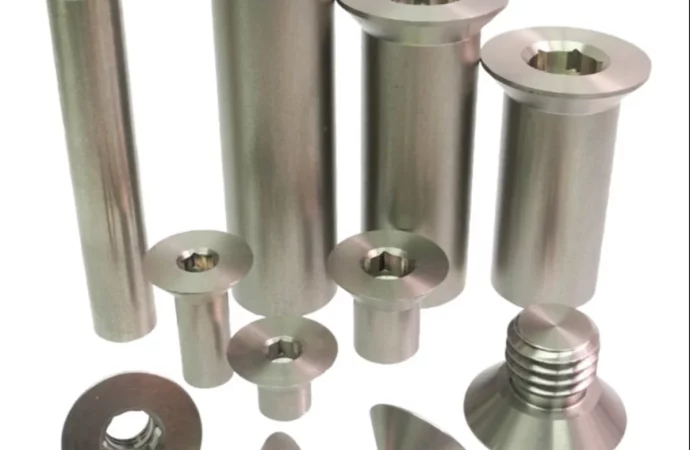

Barrel nuts, also known as cross dowel nuts or sleeve nuts, are cylindrical metal fasteners with internal threading that runs perpendicular to the cylinder’s axis. They are typically used in conjunction with bolts to provide strong, vibration-resistant joints. In playground installations, high-security barrel nuts feature tamper-resistant designs that prevent unauthorized removal or adjustment, making them ideal for public and high-traffic areas.

These nuts are inserted into pre-drilled holes in one component, and a bolt is threaded into the nut from an adjacent component, locking both parts together securely. Their compact form factor and concealed installation make them both functional and visually discreet.

Why High-Security Barrel Nuts Matter in Playgrounds

1. Tamper Resistance for Public Safety

Playground equipment is often exposed to public environments, making it vulnerable to vandalism or unauthorized tampering. High-security barrel nuts are designed with unique drive systems—such as pin-in-Torx, spanner, or one-way slotted heads—that require specialized tools to install or remove. This feature significantly reduces the risk of parts being disassembled by non-maintenance personnel, thereby maintaining structural integrity.

2. Superior Holding Power

Compared to traditional fasteners, barrel nuts provide a more secure fastening system by distributing stress across a larger surface area. When used with bolts, they create a clamp-like connection that withstands dynamic forces such as vibrations, impacts, and heavy use. This is particularly important in playgrounds where equipment endures frequent and energetic activity.

3. Flush and Safe Finishing

Protruding bolts and nuts can pose snagging or scratching hazards, especially in areas accessed by children. Barrel nuts allow for flush installation, where fasteners are recessed or hidden within the structure. This not only enhances aesthetic appeal but also improves safety by eliminating sharp or accessible hardware edges.

Common Applications in Playground Equipment

High-security barrel nuts are commonly used in:

Climbing structures: For assembling modular climbing frames and connecting metal or plastic joints securely.

Swings and seesaws: To provide long-lasting joints that can withstand repetitive motion and stress.

Slides and tunnels: Where strong internal fastening is needed without external projections.

Wooden play systems: As a preferred method for joining timber components where aesthetics and child safety are both critical.

Their versatility and strength make barrel nuts suitable for use in a wide range of playground components, both in indoor and outdoor settings.

Material Considerations

When selecting barrel nuts for playgrounds, material choice is vital. Fasteners must be corrosion-resistant to endure outdoor environments, frequent cleaning, and exposure to elements.

Stainless steel barrel nuts are ideal for their rust resistance and strength, making them suitable for coastal or high-moisture environments.

Zinc-plated steel offers a cost-effective solution for indoor or moderate outdoor use, with some resistance to corrosion.

Brass or aluminum barrel nuts, while less common in playgrounds, may be used where lightweight or non-magnetic properties are required.

It’s also crucial to ensure that the material used in the barrel nuts is compatible with the connected components to prevent galvanic corrosion.

Installation Best Practices

To ensure maximum safety and performance, follow these guidelines when using barrel nuts in playground construction:

Pre-drill accurately: Misalignment between the bolt and barrel nut holes can result in weak joints or difficult installation.

Use appropriate tools: Always use the correct driver bit for the tamper-resistant head to avoid stripping and ensure a secure fit.

Torque control: Avoid over-tightening, which can damage materials or strip threads, and under-tightening, which may cause loosening over time.

Routine inspections: Even tamper-resistant fasteners should be checked periodically during maintenance to ensure they remain secure and undamaged.

Choosing the Right Barrel Nut Supplier

Working with a reliable supplier is critical to obtaining high-quality, tamper-resistant barrel nuts designed specifically for playground safety. Look for manufacturers that offer:

Fasteners tested to meet ASTM and EN safety standards

A variety of head styles for tamper resistance

Material certifications (e.g., stainless steel grades)

Custom options for specialized playground configurations

Partnering with a trusted fastener supplier ensures not only product quality but also expert guidance for your specific project needs.

Conclusion

In the context of playground installations, the importance of reliable and tamper-resistant fastening cannot be overstated. High-security barrel nuts offer an effective solution by combining robust joint integrity with child-safe design features. Their resistance to tampering, clean installation, and compatibility with various materials make them an essential component in modern playground construction.

By selecting the right barrel nuts and following best practices for installation and maintenance, builders and contractors can deliver safer, longer-lasting playgrounds that meet both industry standards and public expectations.

More info visit: https://tokohasil.com