3D printing has come a long way from being a prototyping tool to a core component in full-scale manufacturing. As we step into 2025, the 3D printing landscape is rapidly evolving, driven by advancements in materials, software, and hardware. A modern 3D printing service today offers more than just object creation—it delivers innovation, precision, and

3D printing has come a long way from being a prototyping tool to a core component in full-scale manufacturing. As we step into 2025, the 3D printing landscape is rapidly evolving, driven by advancements in materials, software, and hardware. A modern 3D printing service today offers more than just object creation—it delivers innovation, precision, and scalability across industries. Understanding the future trends in this space is essential for businesses and individuals looking to stay ahead of the curve.

Wider Adoption of Sustainable Materials

One of the most promising trends in 2025 is the increased focus on sustainability. Environmental concerns and regulatory pressure are pushing the industry to adopt more eco-friendly materials. Recycled plastics, biodegradable filaments, and bio-based resins are gaining traction. These materials not only reduce environmental impact but also align with corporate social responsibility goals.

Moreover, advancements in closed-loop systems allow for material reuse, making the 3D printing process more circular and less wasteful. This trend is particularly important for industries with a high volume of production waste.

Growth in Metal 3D Printing

Metal 3D printing is transitioning from niche applications to mainstream manufacturing. In 2025, its use in industries such as aerospace, automotive, and healthcare is expected to expand significantly. Innovations in metal powders, sintering techniques, and hybrid manufacturing systems are making metal 3D printing faster, more cost-effective, and highly precise.

Furthermore, new alloys are being developed specifically for additive manufacturing, allowing engineers to create components with better strength-to-weight ratios and corrosion resistance. These developments make metal 3D printing more attractive for end-use parts, not just prototypes.

AI Integration for Smarter Printing

Artificial intelligence is playing a critical role in optimizing 3D printing workflows. In 2025, AI-driven tools are being widely integrated into design software, enabling automated part orientation, support generation, and print parameter optimization.

Machine learning algorithms can now predict print failures before they happen, reducing waste and improving success rates. AI is also being used for real-time quality control, analyzing layer-by-layer construction to detect anomalies and ensure consistent output. As AI continues to evolve, it will become an indispensable asset in every stage of the 3D printing process.

Expansion of On-Demand Manufacturing

One of the core strengths of 3D printing is the ability to produce parts as needed. In 2025, this trend is being amplified by advancements in cloud-based platforms and decentralized production models. Businesses no longer need to stock large inventories—they can produce parts on demand, closer to the point of use.

This shift supports faster lead times, reduced logistics costs, and more agile supply chains. It also opens up new possibilities for localized production in remote or underserved regions, where traditional manufacturing infrastructure may not be available.

Greater Customization in End-Use Products

Personalization is becoming a key driver in product design, and 3D printing is at the forefront of this movement. From medical implants tailored to a patient’s anatomy to consumer goods designed to individual preferences, customization is more accessible and scalable in 2025.

Advanced scanning technologies and AI-assisted design tools make it easier than ever to create unique, one-off items without increasing production costs. As customer demand for individualized products grows, this trend will only accelerate.

Hybrid Manufacturing Systems

The future is not solely additive or subtractive—it’s a combination of both. Hybrid manufacturing systems that integrate 3D printing with CNC machining, laser cutting, or injection molding are becoming more common in 2025.

These systems offer the best of both worlds: the design freedom of additive manufacturing and the precision of traditional processes. Hybrid systems enable post-processing to be completed in the same setup, improving workflow efficiency and reducing labor costs. They are particularly useful for complex parts that require tight tolerances or multi-material construction.

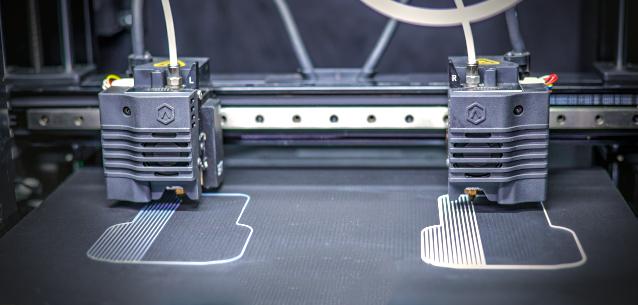

Advances in Multi-Material Printing

2025 is seeing significant improvements in multi-material 3D printing. New printers can handle multiple materials within a single build, allowing for the integration of different mechanical, electrical, or thermal properties into one object.

This opens up new design possibilities, such as creating objects with embedded sensors, flexible joints, or color gradients without additional assembly. The ability to print multi-material objects will be a game-changer for fields like robotics, wearable tech, and smart devices.

Regulatory and Quality Standards Evolution

As 3D printing becomes more mainstream, regulatory bodies are updating their standards to ensure safety, consistency, and reliability. In 2025, standardized certifications for 3D printed parts are more prevalent, especially in regulated sectors such as healthcare and aerospace.

Quality assurance protocols, material traceability, and repeatability testing are becoming integral parts of the 3D printing workflow. These efforts help build trust in 3D printed components and pave the way for broader industrial adoption.

Integration with Digital Manufacturing Ecosystems

3D printing is no longer a standalone technology; it is being integrated into broader digital manufacturing ecosystems. In 2025, seamless communication between CAD software, simulation tools, supply chain platforms, and production hardware is the norm.

This digital thread enables better data sharing, real-time monitoring, and predictive analytics. As a result, businesses can achieve higher efficiency, reduce downtime, and improve product lifecycle management. The convergence of technologies marks a new era in smart manufacturing.

Conclusion

The 3D printing landscape in 2025 is more dynamic, intelligent, and sustainable than ever before. From advanced materials and AI integration to decentralized production and regulatory alignment, the future trends are shaping a world where 3D printing is a central pillar of modern manufacturing. Businesses that embrace these changes will be better positioned to innovate, reduce costs, and meet the evolving demands of their markets.