Creating a safe workplace is more than just a goal—it’s a necessity. Every day, employees face various workplace hazards that can lead to injuries, illnesses, or even fatalities. One of the most effective tools to manage these risks is a Risk Comparison Matrix. This simple yet powerful method helps employers and safety officers identify, compare,

Creating a safe workplace is more than just a goal—it’s a necessity. Every day, employees face various workplace hazards that can lead to injuries, illnesses, or even fatalities. One of the most effective tools to manage these risks is a Risk Comparison Matrix. This simple yet powerful method helps employers and safety officers identify, compare, and prioritize hazards, making it easier to implement safety measures that save lives.

In this article, we will explore what a Risk Comparison Matrix is, why it’s essential for workplace safety, and provide a detailed step-by-step guide on how to create one. We’ll also include real-world examples and share why investing in safety courses, such as Safety Officer Courses in Pakistan, can make a significant difference in managing workplace risks effectively.

What is a Risk Comparison Matrix?

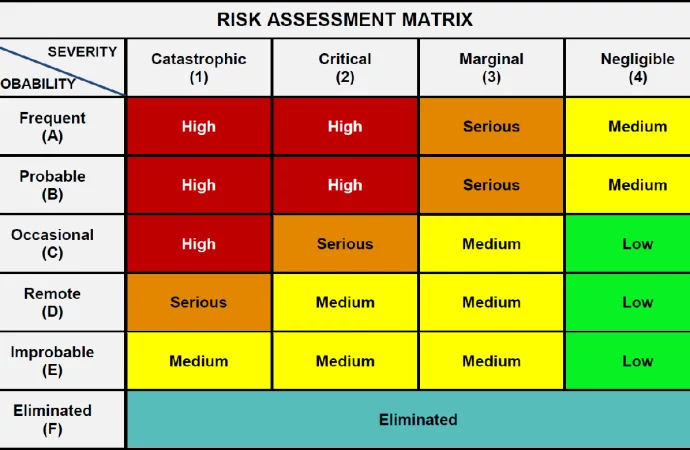

A Risk Comparison Matrix (also known as a Risk Assessment Matrix) is a visual tool that helps organizations evaluate and compare the level of risk associated with different hazards in the workplace. The matrix usually plots the likelihood of a hazard occurring against the severity of its potential consequences.

By plotting hazards in this way, companies can see at a glance which risks are most critical and need urgent attention. This method allows for better decision-making and resource allocation to reduce workplace accidents.

Why is a Risk Comparison Matrix Important for Safer Workplaces?

Imagine a factory floor with dozens of hazards: slippery floors, faulty machinery, electrical risks, and chemical exposure. Without a clear way to prioritize, it’s hard for safety teams to know which risks to tackle first. This is where the Risk Comparison Matrix becomes invaluable.

Using the matrix helps:

- Identify the most dangerous hazards quickly

- Focus on risks that could cause severe injury or death

- Allocate safety resources efficiently

- Increase employee awareness and engagement in safety practices

- Improve compliance with safety regulations

Step-by-Step Guide to Creating a Risk Comparison Matrix

Creating a Risk Comparison Matrix can seem overwhelming at first, but breaking it down into simple steps makes it manageable for any workplace.

Step 1: Identify Workplace Hazards

Begin by conducting a thorough hazard identification process. Walk through the workplace and look for anything that could potentially cause harm. This includes physical hazards (like machinery or falling objects), chemical hazards, ergonomic risks, and even psychosocial risks like stress.

Example: In a warehouse, common hazards might include heavy lifting, forklifts moving around, and uneven floors.

Step 2: Determine the Likelihood of Each Hazard Occurring

Next, estimate how often each hazard is likely to cause an incident. This could be categorized as:

- Rare (happens once in a long while)

- Unlikely

- Possible

- Likely

- Almost Certain

This assessment is usually based on past incident data, expert opinion, or industry standards.

Step 3: Assess the Severity of Potential Harm

Evaluate how severe the consequences would be if the hazard did cause harm. Severity can range from:

- Insignificant (minor scratches)

- Minor (first aid needed)

- Moderate (medical treatment required)

- Major (serious injury or illness)

- Catastrophic (death or permanent disability)

Step 4: Create the Matrix Grid

Draw a grid with likelihood on one axis and severity on the other. Each cell in the grid corresponds to a risk level. For example:

| Severity \ Likelihood | Rare | Unlikely | Possible | Likely | Almost Certain |

| Catastrophic | Medium | High | High | Very High | Very High |

| Major | Low | Medium | High | High | Very High |

| Moderate | Low | Low | Medium | High | High |

| Minor | Low | Low | Low | Medium | Medium |

| Insignificant | Low | Low | Low | Low | Low |

Step 5: Plot Each Hazard on the Matrix

Using your hazard data, plot each identified hazard in the matrix according to its likelihood and severity. This visual representation quickly shows which hazards are of high risk and demand immediate action.

Step 6: Prioritize and Plan Risk Controls

Focus on the hazards located in the high and very high-risk areas first. Develop control measures such as:

- Engineering controls (machine guards, ventilation)

- Administrative controls (training, procedures)

- Personal Protective Equipment (PPE)

Step 7: Review and Update Regularly

Workplace hazards can change over time, so it’s important to review and update the Risk Comparison Matrix regularly. This ensures ongoing workplace safety and compliance with regulations.

Real-Life Example: How a Risk Comparison Matrix Saved Lives

In a manufacturing plant, the safety team noticed frequent near misses involving forklift trucks. Using a Risk Comparison Matrix, they ranked the forklift-related hazards as “Very High” due to the combination of likely occurrence and potential for catastrophic injury.

By prioritizing this risk, the company implemented stricter forklift operation training, installed better signage, and introduced speed limits inside the plant. Within six months, forklift-related incidents dropped by 70%, proving how a simple risk matrix can lead to major safety improvements.

Why Safety Training is Crucial: Spotlight on the Safety Officer Course in Pakistan

No matter how sophisticated your risk tools are, they’re only as effective as the people using them. That’s why investing in proper safety training is vital. For professionals in Pakistan, the Safety Officer Course offers hands-on training in hazard identification, risk assessment, and safety management systems.

By enrolling in this course, safety officers gain the knowledge and confidence to create and use tools like the Risk Comparison Matrix effectively. This not only protects workers but also helps organizations comply with local laws and international safety standards.

Read More: Find Affordable Safety Courses in Pakistan Here

Tips for Making Your Risk Comparison Matrix More Effective

- Engage your team: Involve workers from different departments to get a clearer picture of hazards.

- Use software tools: Digital risk matrices can help update and share assessments easily.

- Communicate results: Share the matrix findings with all employees to raise awareness.

- Combine with other tools: Use alongside safety audits and incident reports for a comprehensive safety program.

Final Thoughts

A Risk Comparison Matrix is more than a chart—it’s a powerful safety communication tool. When created thoughtfully, it helps workplaces identify risks, prioritize actions, and protect their most valuable asset: their people.

If you’re serious about making your workplace safer, start with a matrix to understand your risks clearly. Pair this with solid training, like the Safety Officer Course in Pakistan, and you’ll be on your way to reducing accidents and boosting employee confidence.

How does your company manage workplace risks? Have you used a risk matrix before? Share your experiences in the comments below!