3D metal printing, or metal additive manufacturing, is rapidly transforming production processes by enabling the fabrication of intricate metal components that are challenging to produce using conventional techniques. This novel approach fabricates metal components one layer at a time, providing designers with enhanced flexibility and improved resource use. By 2024, metal 3D printing became more

3D metal printing, or metal additive manufacturing, is rapidly transforming production processes by enabling the fabrication of intricate metal components that are challenging to produce using conventional techniques. This novel approach fabricates metal components one layer at a time, providing designers with enhanced flexibility and improved resource use.

By 2024, metal 3D printing became more accessible and was extensively utilized across various sectors, including fashion, healthcare, aviation, and others. Metal 3D printing continues to improve in its capabilities, applications, and benefits for users. This presents a promising future for innovative designs and enhanced production techniques.

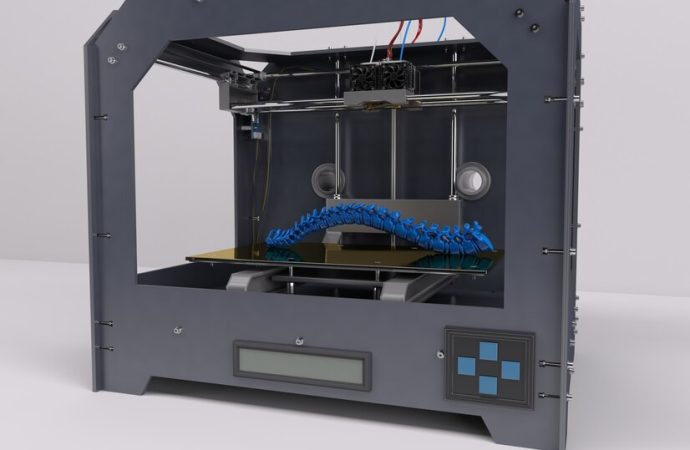

How it Works to 3D Print Metal

Image by Yandex.com

Metal 3D printing involves a process where metal powders or filaments are fused using high-precision lasers or electron beams. The most common techniques include:

- Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS): These involve laser fusion to produce strong, precise metal parts.

- Binder Jetting: A powder-based process where a binder is added to metal powders, followed by sintering in a furnace.

- Electron Beam Melting (EBM): Using an electron beam instead of a laser, EBM is particularly useful for high-density parts in aerospace and medical applications.

These processes offer significant design flexibility, allowing for intricate geometries, lightweight structures, and material efficiency previously unattainable with traditional subtractive manufacturing.

Pros of 3D printing metal

3D metal printing is useful for many areas of manufacturing and product creation, including:

A. Capabilities for Complex Design

One of the best things about metal 3D printing is that it lets you make complicated designs that would be hard or too expensive to make any other way. Manufacturers can make shapes with complex internal structures, which cuts down on waste and makes parts that are lighter and stronger.

B. Material Efficiency and long-Term use

Metal 3D printing saves resources because it only needs the right amount of material for each layer, so there is less waste. A lot of companies want to be more environmentally friendly, and this method fits with their goals.

C. Rapid Prototyping and Time Efficiency

Image by Yandex.com

Companies can make prototypes and working parts in days instead of weeks with metal 3D printing, which shortens the time it takes to build new products. This quick turn-around makes testing, iteration, and production scale go more quickly.

Costs Going Down in Small Batch Production

When it comes to making unique or low-volume parts, 3D metal printing is cheaper than traditional methods that need expensive molds or tools. This benefit is especially useful in fields like aircraft, where parts are often made to order or in small quantities.

E. Production on demand and a flexible supply chain

With 3D metal printing, you can make things when you need them, so you don’t have to keep a lot of stock on hand. This makes the supply chain simpler. Parts can be printed on-site or close to where they will be used, which cuts down on wait times and shipping costs.

Latest Trends in Metal 3D Printing

As metal 3D printing technology evolves, several key trends are shaping its development and application:

A. 3D printing of multiple materials

Multi-material printing lets makers make parts with different material properties all in one piece, which is what researchers are looking into right now. This trend can help you make parts that last longer, don’t wear out as quickly, or conduct electricity better.

B. Higher print speeds and bigger build volumes

As printer technology has improved, build volumes have grown. This lets you make bigger parts all at once. Faster laser and electron beam systems are also cutting down on print times, which makes things even more productive.

C. Better quality control with AI and machine learning

Metal 3D printing systems are getting AI and machine learning techniques added to them to keep an eye on the printing process and make sure it’s always the same. These technologies help find problems right away, which improves quality and cuts down on work that needs to be done after the fact.

D. Better techniques for post-processing

In the past, post-processing has taken a lot of time in metal 3D printing. But improvements in automatic support removal, surface finishing, and heat treatment have made printed parts better and cut down on the time needed for finishing.

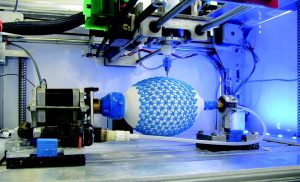

E. Expansion in Material Choices

Image by Yandex.com

Metal 3D printing materials are diversifying beyond stainless steel and titanium. New alloys like Inconel and copper blends have opened up more opportunities in industries such as electronics and medical devices, where specific material properties are required.

Applications and Examples of Metal 3D Printing

Metal 3D printing’s versatility makes it a perfect fit for various industries, from medical devices to automotive components. Here are some prominent applications:

Aerospace and Defense

The aerospace sector has embraced metal 3D printing for its ability to produce lightweight, strong, and heat-resistant components. For example, GE Aviation has used metal 3D printing to produce fuel nozzles for jet engines. These printed nozzles are 25% lighter and five times more durable than traditionally manufactured parts.

Medical Implants and Prosthetics

Metal 3D printing is critical in creating custom prosthetics and implants tailored to individual patients. Stryker, a medical technology company, uses metal 3D printing to create titanium implants with complex lattice structures that promote bone growth and better integration with human tissue.

Automotive Prototyping and Custom Parts

Automotive manufacturers leverage metal 3D printing to produce custom parts for high-performance vehicles. Bugatti, for instance, used metal 3D printing to develop brake calipers made of titanium, reducing weight and increasing performance.

Tooling and Molds

Image by Yandex.com

Companies like Siemens use metal 3D printing to create custom tools and molds quickly, streamlining the manufacturing process and reducing downtime. This approach is particularly beneficial in industries that require frequent tool changes or custom molds.

Energy and Industrial Applications

Metal 3D printing is used to produce durable components for energy applications, such as turbines and heat exchangers. Siemens Energy developed a 3D-printed gas turbine blade that withstands high temperatures and pressure, enhancing efficiency and durability in power generation.

Case Studies: Success Stories in Metal 3D Printing

Real-world examples of metal 3D printing highlight its transformative impact on various industries:

GE Aviation’s Fuel Nozzle

GE Aviation adopted metal 3D printing to manufacture fuel nozzles for its LEAP jet engines. Traditional manufacturing required 20 separate pieces to be welded together, whereas 3D printing consolidated this into a single piece, reducing weight by 25% and enhancing durability. The new nozzle improved fuel efficiency and cut down on manufacturing time, proving the cost-effectiveness of metal 3D printing in high-stakes applications.

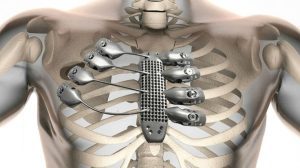

Stryker’s Titanium Implants

Image by Yandex.com

Stryker uses metal 3D printing to create patient-specific titanium implants. These implants feature complex lattice structures that encourage natural bone growth and improve the stability of the implant. Stryker’s use of metal 3D printing has improved patient outcomes and reduced time in surgery, demonstrating the technology’s value in healthcare.

NASA’s Rocket Engine Components

NASA has used metal 3D printing to produce rocket engine parts, reducing the manufacturing timeline from months to days. In one instance, a 3D-printed fuel injector performed well under high-stress testing, paving the way for further exploration of metal 3D printing in space exploration. The reduced production time and cost savings are substantial, allowing NASA to focus more resources on mission planning and development.

Challenges in Metal 3D Printing Manufacturing

While metal 3D printing has numerous advantages, it also faces several challenges that must be addressed as the technology advances.

A. High Initial Costs

The cost of metal 3D printing equipment and materials remains high, making it difficult for smaller companies to invest in this technology. However, as the technology becomes more mainstream, costs are expected to decrease.

B. Quality and Consistency Concerns

Ensuring quality and consistency in metal 3D printing is challenging, particularly for industries requiring high-precision parts. Variations in print quality can result from material inconsistencies or printer settings, necessitating stringent quality control.

C. Limited Material Options

While the range of materials is expanding, there are still limitations in the types of metals available for 3D printing. Specific applications may require properties that are not yet achievable with existing materials.

D. Post-Processing Requirements

Many 3D-printed metal parts require post-processing, such as heat treatment, to achieve desired properties. This additional step adds time and cost, reducing the overall efficiency of the printing process.

What’s Next for 3D Printing Metal

Metal 3D printing is about to grow and change in big ways. As prices go down and more materials become available, more businesses will use the technology for different tasks. AI and machine learning improvements will make quality control better, and blockchain may make production data safer.

There will probably be a lot more focus on reusing and using resources efficiently in the future, and metal 3D printing will be a big part of that. Metal 3D printing will continue to be used in aerospace, healthcare, and the auto industry to make complicated, lightweight, and high-performance parts, which will lead to the next generation of innovations.

Conclusion

3D metal printing is changing the way that goods are planned, made, and sent to customers. Metal 3D printing is being used more and more in many fields because it is flexible, environmentally friendly, and efficient. It is also pushing the limits of what is possible in production.

As technology improves, metal 3D printing will bring us closer to a world where creativity is the only thing that stops people from coming up with new ideas. It will do this by offering cost-effective solutions, cutting down on waste, and giving us more design options than ever before. Metal 3D printing is just getting started, and businesses all over the world can look forward to exciting changes.