The Author’s Perspective As a keen observer of technological advancements in manufacturing, I’ve delved into the transformative potential of 3D printing. This article explores the profound impact of additive manufacturing on traditional production methods and industry landscapes. Introduction to 3D Printing in Manufacturing 3D printing, or additive manufacturing, involves creating three-dimensional objects layer by layer

The Author’s Perspective

As a keen observer of technological advancements in manufacturing, I’ve delved into the transformative potential of 3D printing. This article explores the profound impact of additive manufacturing on traditional production methods and industry landscapes.

Introduction to 3D Printing in Manufacturing

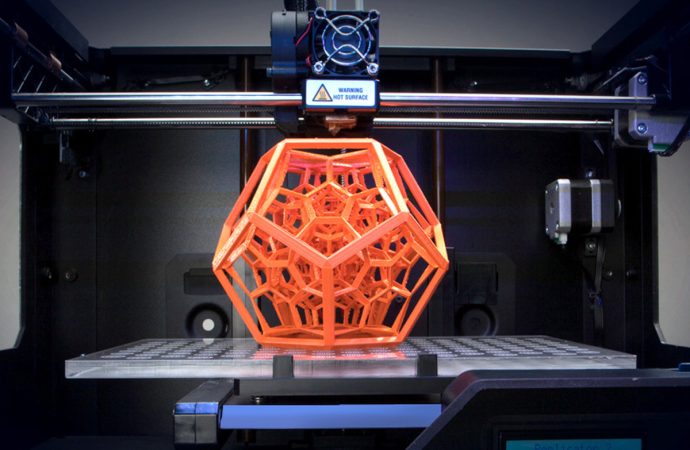

3D printing, or additive manufacturing, involves creating three-dimensional objects layer by layer from digital models, revolutionizing traditional manufacturing processes with its versatility and efficiency.

Advantages of 3D Printing

Highlighting benefits such as rapid prototyping, reduced lead times, cost-effectiveness for low-volume production, complex geometries, and the ability to manufacture customized products on demand.

Applications Across Industries

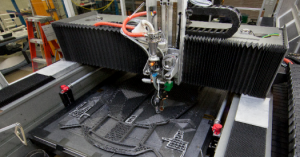

Image by : Yandex

Exploring diverse applications in aerospace, automotive, healthcare (medical devices and prosthetics), consumer goods, architecture, education, and defense, showcasing how 3D printing is reshaping production methods.

Customization and Design Freedom

Discussing how 3D printing enables intricate designs, personalization of products, and the freedom to create complex shapes and structures that are difficult or impossible to achieve with traditional manufacturing techniques.

Supply Chain Efficiency

Examining the potential for localized manufacturing, reduced inventory costs, on-demand production, and supply chain resilience through 3D printing, minimizing logistical challenges and improving responsiveness to market demands.

Impact on Prototyping and Product Development

Highlighting the role of 3D printing in accelerating product development cycles, enabling iterative design improvements, and facilitating rapid prototyping for testing and validation before full-scale production.

Sustainability and Environmental Benefits

Addressing how 3D printing can contribute to sustainability goals by reducing material waste, energy consumption, and carbon emissions compared to traditional manufacturing methods, promoting eco-friendly production practices.

Challenges and Limitations

Discussing challenges such as material limitations, scalability for mass production, quality assurance standards, regulatory compliance, intellectual property issues, and the need for skilled workforce training.

Future Trends and Innovations

Speculating on future trends such as advancements in materials (biocompatible and recyclable materials), multi-material printing, 4D printing (materials that change shape over time), and integration with AI for autonomous manufacturing processes.

Embracing the Future of Manufacturing

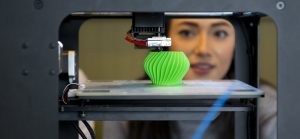

Image by : Yandex

As 3D printing continues to evolve, its impact on manufacturing is undeniable, offering transformative possibilities for innovation, efficiency, and sustainability. Embracing additive manufacturing technologies can lead to a more agile, competitive, and sustainable future for industries worldwide.