Although robotics has always captivated people, new developments are hastening its industry-wide integration. Medical robots are improving precision surgery, and humanoid robots are improving manufacturing. AI-powered robots are changing logistics and warehouse automation, while soft robotics is revolutionizing agriculture. Robotics has the potential to significantly increase productivity, sustainability, and safety with further development. With the

Although robotics has always captivated people, new developments are hastening its industry-wide integration. Medical robots are improving precision surgery, and humanoid robots are improving manufacturing. AI-powered robots are changing logistics and warehouse automation, while soft robotics is revolutionizing agriculture. Robotics has the potential to significantly increase productivity, sustainability, and safety with further development. With the help of case studies and real-world examples, this article examines the several industries where robotics is having an impact.

Construction and Housing Automation: Building the Future with Robotics

Overview

Construction is another sector where robotics is making strides. The collaboration between AUAR, ABB Robotics, and Rival Holdings is introducing robotic micro-factories for sustainable homebuilding.

Benefits

- Faster Construction: Robots can build homes more quickly and with greater accuracy than traditional methods.

- Sustainability: Automated systems reduce material waste, contributing to more environmentally friendly construction practices.

Example

Robotic Micro-Factories for Housing: The project by AUAR and ABB Robotics involves setting up robotic systems that can manufacture construction materials and assemble homes. These micro-factories reduce the time needed to build homes, providing an affordable, efficient solution for addressing housing shortages.

Soft Robotics for Healthcare: Handling the Delicate Touch

Overview

Soft robotics focuses on creating robots with flexible, deformable structures that are ideal for handling delicate tasks. Researchers are developing soft robots that can be used for drug delivery, particularly in sensitive environments such as the human body.

Benefits

- Delicate Handling: Soft robots can handle fragile items, such as tissues or small organs, without causing damage.

- Minimally Invasive: Their flexibility allows soft robots to navigate through narrow or hard-to-reach spaces, making them ideal for medical applications.

Case Study

Soft Robots for Drug Delivery: Researchers are designing small, flexible robots that can travel through the bloodstream to deliver medication directly to the site of illness, offering a more targeted approach than traditional methods.

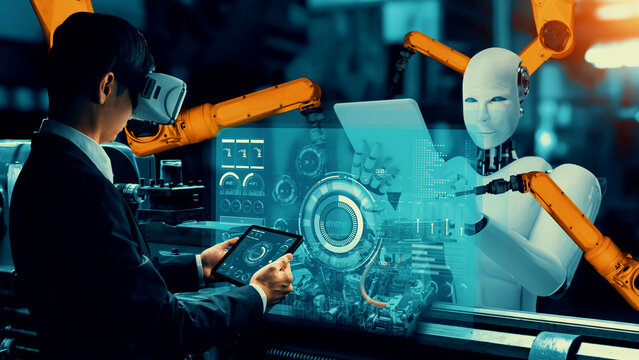

Collaborative Robotics: Enhancing Human-Robot Interaction

Image by Yandex.com

Overview

Collaborative robots, or cobots, are designed to work safely and efficiently alongside humans, performing tasks that would otherwise require manual labor. These robots are rapidly being adopted across industries, particularly in manufacturing environments. Unlike traditional industrial robots, which are typically confined to cages or restricted areas, cobots can work in direct collaboration with workers, boosting both productivity and safety.

Benefits

- Enhanced Efficiency: Cobots can handle repetitive tasks, allowing human workers to focus on more complex operations, ultimately increasing overall production output.

- Improved Worker Safety: Cobots are designed with sensors that prevent accidents, making them safer than traditional industrial robots that may operate in hazardous conditions.

- Cost-Effective: Cobots are generally less expensive and easier to program than traditional industrial robots, making them a practical solution for small and medium-sized enterprises (SMEs).

Example

Comau’s SmartReach Cobots: Comau, a leader in automation, has developed the SmartReach series of cobots, which are designed for complex tasks such as assembly, packaging, and quality inspection. These cobots are easy to integrate into existing production lines and require minimal programming, allowing businesses to reap the benefits of automation quickly and efficiently. Their collaborative nature also allows them to work directly alongside human operators without the need for safety barriers.

Soft Robotics for Delicate Handling: Revolutionizing Healthcare and More

Overview

Soft robotics is an emerging field that focuses on creating robots with flexible, deformable structures, allowing them to perform tasks that require a delicate touch. These robots are increasingly being used in healthcare, particularly for drug delivery, surgical procedures, and rehabilitation therapies. Soft robots are uniquely suited for medical applications because they can safely interact with fragile environments, such as human tissue and internal organs.

Benefits

- Non-invasive Procedures: Soft robots can access difficult-to-reach areas of the body without causing damage or discomfort, making them ideal for non-invasive surgeries and diagnostics.

- Gentle Handling: Their flexible structure allows them to interact with delicate objects, reducing the risk of damage to sensitive tissues, organs, or small components.

- Targeted Drug Delivery: Soft robots can be used to deliver medication directly to specific areas of the body, increasing the effectiveness of treatments.

Case Study

Soft Robots for Minimally Invasive Surgery: Researchers are working on developing soft robots that can navigate through the bloodstream to deliver drugs or even perform surgery inside the body. One notable development is a soft robot that can enter the bloodstream, reach specific areas, and deliver treatment with a high degree of precision. This could revolutionize how doctors treat conditions like cancer, targeting tumors with minimal damage to surrounding tissues.

AI-Driven Innovations in Robotic Vision: Enhancing Perception for Autonomy

Image by Yandex.com

Overview

Artificial intelligence (AI) is transforming the capabilities of robots, particularly in the area of vision. Advanced computer vision systems enable robots to perceive and interpret their surroundings, allowing them to navigate complex environments and interact with objects. By mimicking human vision, AI-powered robots can identify objects, recognize faces, and even operate autonomously in unpredictable environments.

Benefits

- Autonomous Navigation: Robots equipped with advanced vision systems can move through dynamic environments without human intervention, improving efficiency in tasks like warehouse management, delivery, and autonomous vehicles.

- Object Recognition: AI-enabled robots can identify and interact with objects in ways that were once only possible for humans, improving accuracy in tasks like assembly, sorting, and packaging.

Example

AI-Powered Vision Systems in Robotics: Researchers are developing vision systems inspired by the way human eyes work. For example, some systems mimic the visual processing that allows the brain to focus on objects in motion. Such innovations are particularly beneficial in industrial robots used for sorting and packaging, where precision is critical. These AI-driven systems allow robots to make real-time decisions based on the objects they see, improving efficiency and accuracy.

Collaborative Robotics in Manufacturing: Transforming the Workforce

Overview

Collaborative robots, or cobots, are gaining popularity in manufacturing environments where human workers and robots work side by side. Unlike traditional robots, which are confined to cages for safety, cobots are designed with sensors and safety features that allow them to operate safely alongside people. These robots are particularly useful in tasks that require precision, repetitive motion, or heavy lifting.

Benefits

- Increased Productivity: Cobots can perform repetitive tasks, freeing up human workers to focus on more complex or creative aspects of production.

- Cost Savings: Cobots are typically more affordable and easier to deploy than traditional industrial robots, making them accessible to small and medium-sized enterprises.

- Improved Worker Safety: Cobots are equipped with sensors that detect the presence of humans, ensuring they do not accidentally injure workers during operation.

Example

Universal Robots’ UR Series: Universal Robots offers a series of cobots that are designed for use in small to medium-sized production environments. These robots are easy to program, flexible, and capable of working with humans. For example, their UR10 robot is ideal for tasks like assembly, packaging, and quality control. These robots are particularly effective in small workshops where they can assist human workers without the need for large, expensive automation systems.

Robotics in Emergency Response: Enhancing Safety and Efficiency

Overview

Robotics is increasingly being used in emergency response scenarios, such as search and rescue missions, disaster recovery, and hazardous material handling. These robots are designed to navigate dangerous environments and perform tasks that would put human lives at risk. From drones that can survey disaster zones to robots that can enter burning buildings, these technologies are revolutionizing how first responders manage emergencies.

Benefits

- Improved Safety: Robots can perform dangerous tasks in hazardous environments, reducing the risk to human lives.

- Efficiency: Robots can access areas that are difficult or unsafe for humans to reach, providing real-time data and insights to improve decision-making during emergencies.

- Versatility: Robots can be equipped with various tools for different tasks, such as mapping disaster areas, searching for survivors, or detecting hazardous materials.

Example

Search and Rescue Robots in Disaster Zones: During the aftermath of natural disasters like earthquakes or floods, robots have been deployed to search for survivors. These robots are equipped with cameras, sensors, and tools to navigate through rubble, detect signs of life, and relay important information back to human rescuers. For example, a robot designed for urban search and rescue was used in Japan after the 2011 tsunami, helping locate survivors in collapsed buildings.

Micro and Nano Robotics: The Future of Medicine and Manufacturing

Overview

Micro and nano robots are tiny machines that operate at the scale of micrometers or nanometers. These robots are capable of performing highly specialized tasks, such as targeted drug delivery, precise medical diagnostics, or repairing materials at the molecular level. Researchers are exploring the potential of micro and nano robots in fields like healthcare, where they could be used for minimally invasive procedures or to treat conditions at the cellular level.

Benefits

- Precision: Micro and nano robots can perform tasks with extraordinary precision, making them ideal for delicate medical procedures or the manipulation of small-scale objects in manufacturing.

- Minimally Invasive: These tiny robots can be used to perform tasks without requiring large incisions, reducing recovery times and the risk of complications.

Case Study

Nano-Robots for Targeted Drug Delivery: Researchers are working on developing nano-robots capable of traveling through the bloodstream to deliver drugs directly to targeted cells. These robots could revolutionize treatments for conditions like cancer, where traditional methods often harm healthy tissue. By delivering medication directly to the site of illness, these robots could significantly improve the effectiveness of treatments.

Conclusion: Robotics’ Future

Robotics’ quick development is changing industries in previously unheard-of ways. The promise of robotics is endless, ranging from humanoid robots that enhance manufacturing processes to tiny robots that transform medicine. We can anticipate even more inventive uses of technology as it develops further, which will change how we live, work, and engage with the world. We are just beginning to explore the enormous potential of the robotic future.